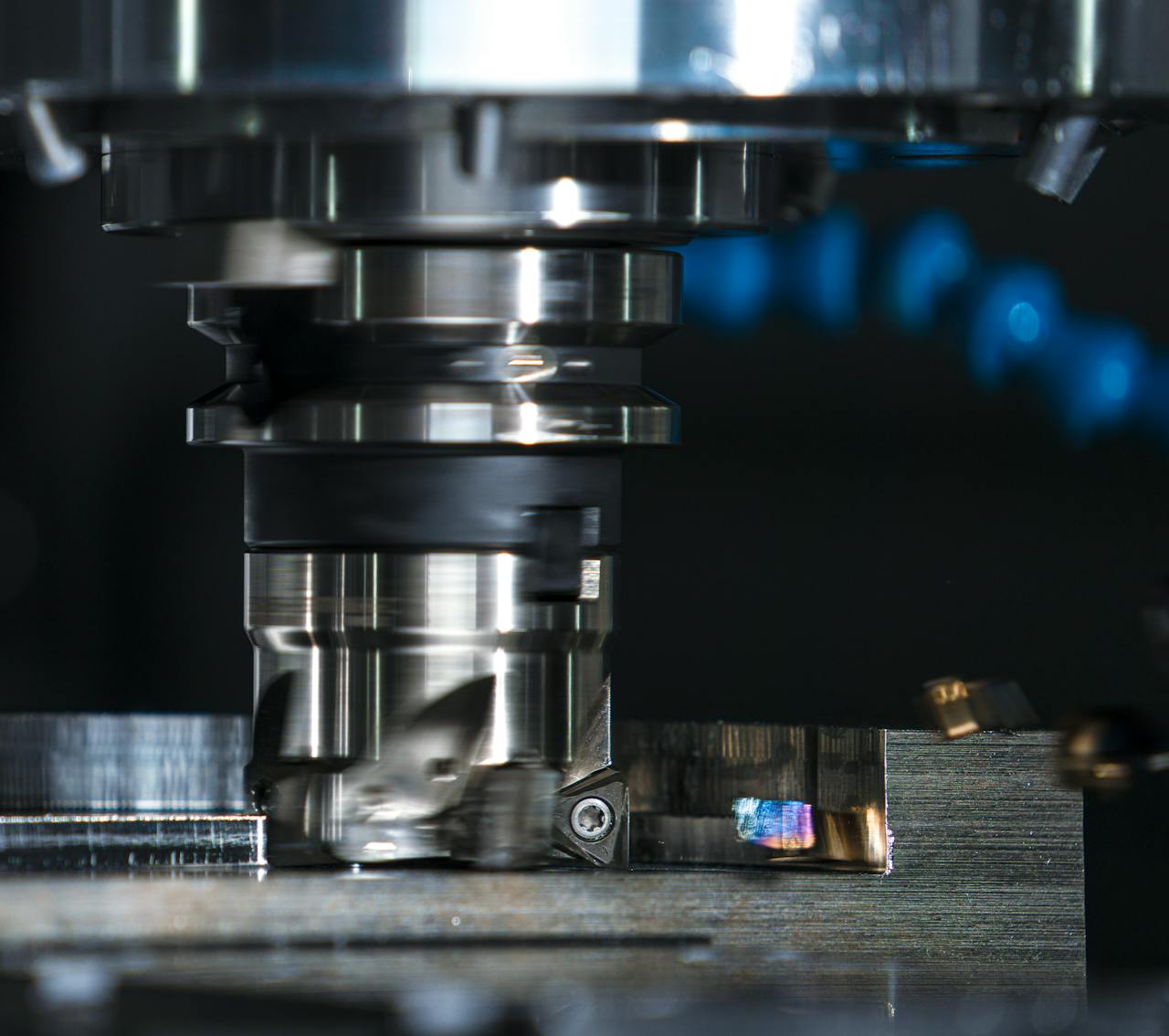

Precision-Engineered Solutions for Your Die Casting Needs

At Proficient Tool, we understand that the foundation of successful die casting lies in the precision and durability of your tooling. With over three decades of dedicated experience, we specialize in the design and construction of high-quality injection molds, including DME-type unit dies and advanced four-slide technology tooling. Our expertise extends to crafting intricate tools for Techmire and Dynacast zinc multi-slide applications, as well as all sizes of unit dies and custom standalone molds. Leveraging industry-leading software like SolidWorks® and UniGraphics®, our team meticulously designs each tool to meet the exact specifications of your project, ensuring optimal performance and longevity.

Expert Design for Enhanced Production Efficiency

Our deep understanding of part geometry, coupled with our expertise of draft requirements and gating strategies, translates directly into superior part finishes and reduced porosity. We meticulously analyze each component to optimize material flow and minimize potential defects, resulting in consistently high-quality castings. This proactive approach not only enhances the aesthetic and functional quality of your products but also significantly extends the lifespan of your tooling. By considering the long-term operational needs of your production, we design tools that deliver sustained performance and reliability.

Serviceable Components for Reduced Downtime

Recognizing the critical importance of minimizing downtime, Proficient Tool incorporates serviceability into the core of our tool design philosophy. During the preliminary design phase, we identify components susceptible to wear and strategically engineer them for easy replacement. This forethought allows for swift maintenance and component replacement, ensuring that your production line remains operational and efficient. By prioritizing serviceable components, we empower you to maintain peak productivity and minimize costly interruptions, securing your investment for years to come. Trust Proficient Tool to deliver new tooling solutions that are not only precisely engineered but also built for enduring performance.

The global mold steel market is projected to witness robust growth, with a Compound Annual Growth Rate (CAGR) of approximately 5-7% over the next five years, fueled by the rise in injection molding applications and a resurgence in manufacturing activities globally.